Moulding Facility

Hydraulic Vacuum Compression Moulding Machine

In Vacuum compression molding presses it automatically cut the edges. We are utilized for trimmed rubber, silicone, and composites materials. Vacuum pressure shaping presses significantly improve the embellishment quality and increment creation up to half. We framing measures in which a material is set straightforwardly into a warmed metal form then, at that point is relaxed by the warmth and accordingly compelled to adjust to the state of the shape, as the form closes. Normally, we use this for rubber-based product manufacturing.

Hydraulic Compression Moulding Machine

In the Compression forming measure, the material is set straightforwardly into a warmed metal form with a water-powered pressing factor then, at that point is mellowed by the warmth and accordingly compelled to adjust to the state of the shape, as the shape closes. Normally, pressure shaping machines open along with an upward hub. This gives a thick and completed surface of the elastic in a water-driven pressing factor medium. In our industry, we officially utilize this Compression Molding Machine for hard material framing.

Manual Compression Moulding Machine

We are occupied with offering Manual Hydraulic Compression Molding for the Rubber assembling measure. In this interaction, we handle the rubber blend particularly associated through the Manual Compression measure. It gives an excellent creation relatively higher than the other pressure measure in our organization we having an accomplished staff to deal with the blend. Our staff did the creation in this particular interaction alone to accomplish a great item. In the manual interaction, our staff distinguishes the progressions and disposes of the flaws by checking the Compression Molding near him.

Video

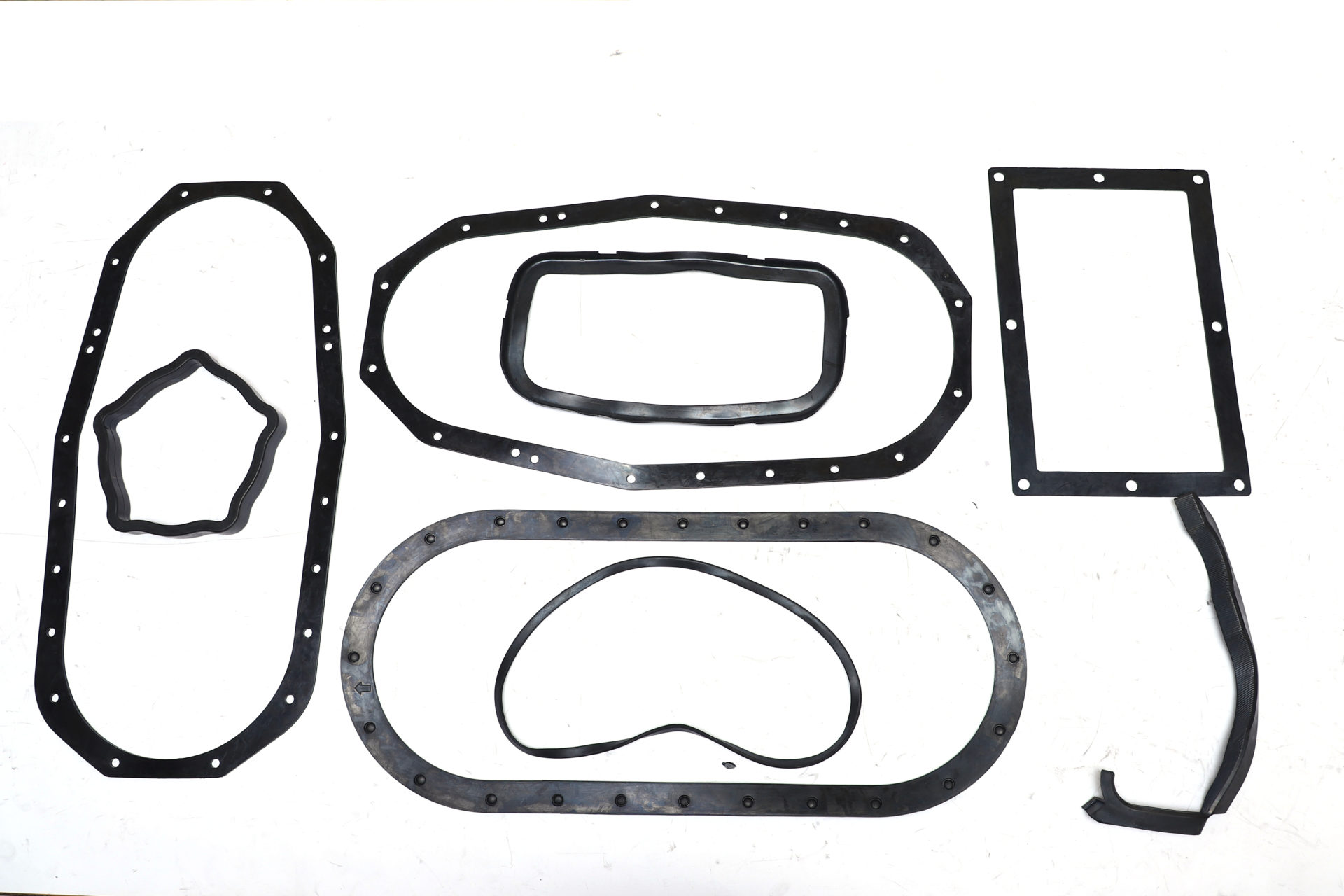

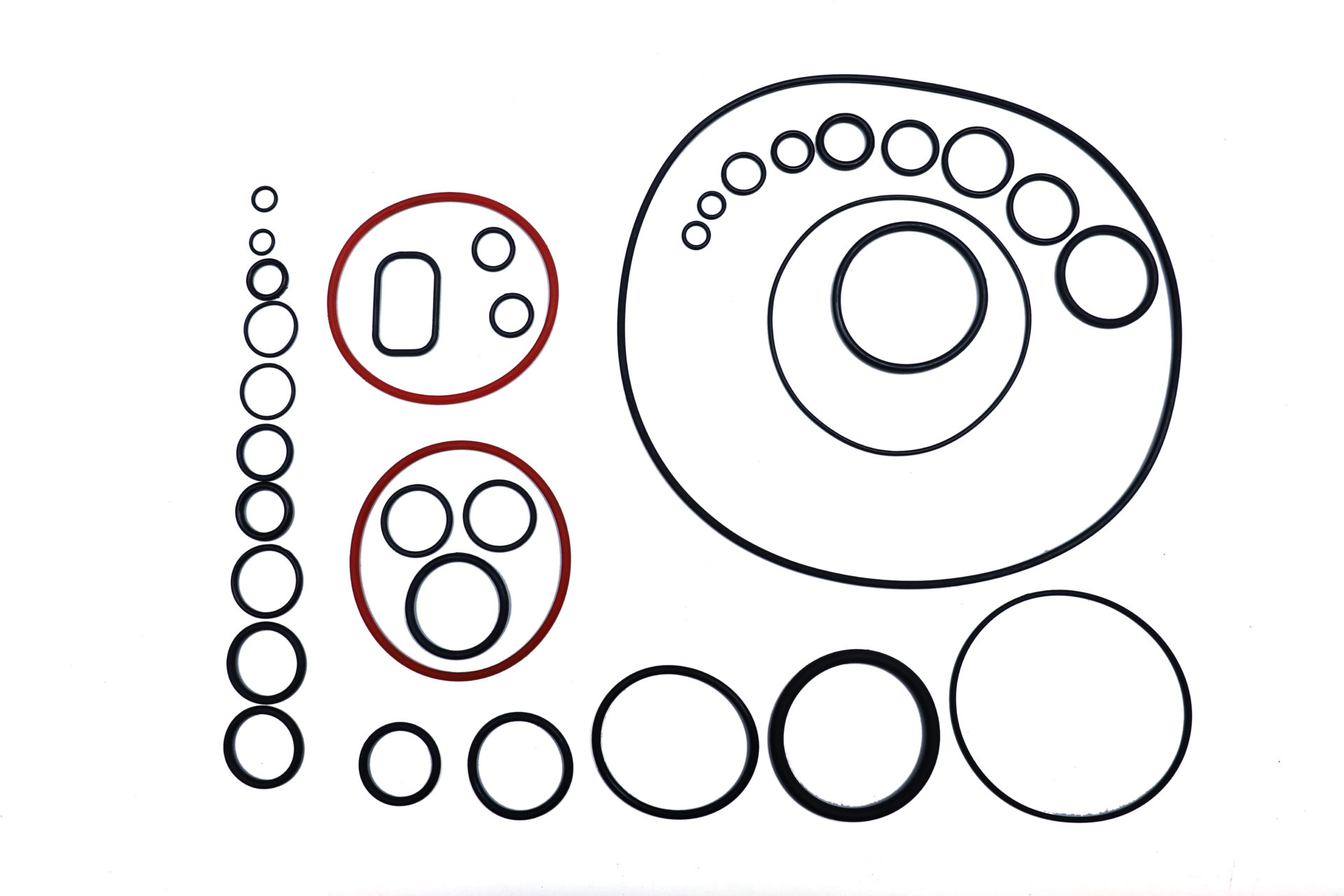

Moulding Products

Previous

Next